Our Products

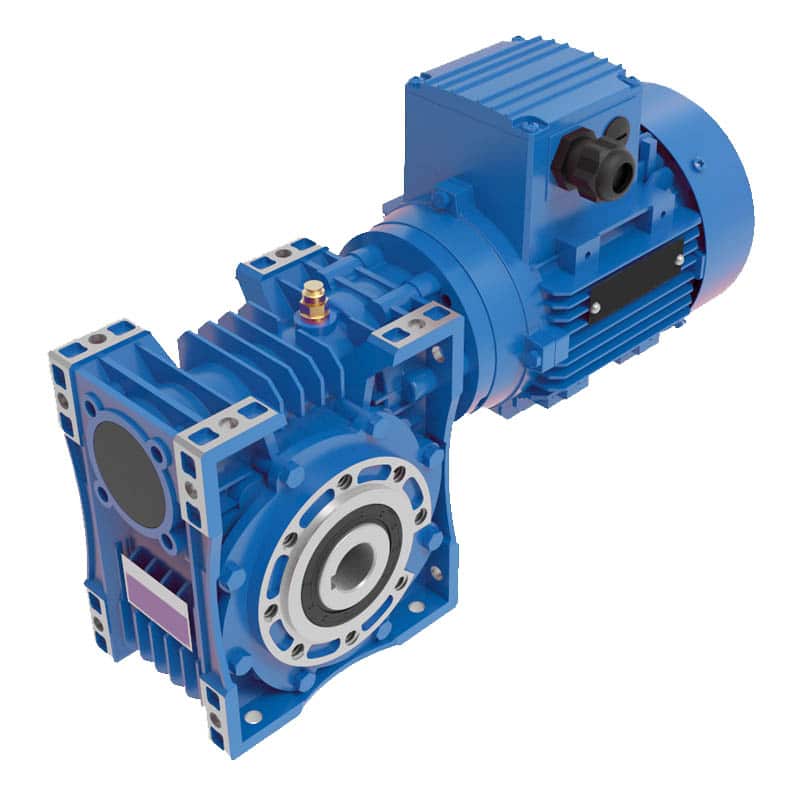

worm geared gearboxes

Worm gear speed reducers range is a brand new product generation of products developed by our company. They are characterized by a kinematic motion made of a casehardened and tempered steel worm with a ground thread and a wheel made out of a spheroidal graphite cast iron hub with addition of bronze. This series are made up for 9 sizes with ratios from 1:7.5 until 1:100, are manufactured in die-cast aluminium frame up to the model 90 and in grey cast iron sizes 110 and 130. As an extension range we have avaliable 3 sizes of pre-stage helical units PR, combination of double worm gearmotors, single and double output shafts and torque arms.

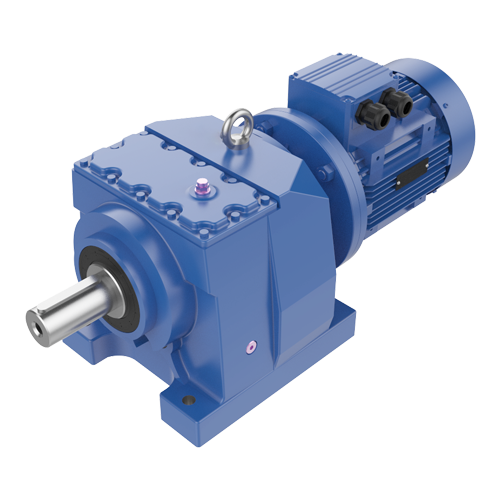

FOOT MOUNTED HELICAL GEARBOXES

・ Monoblock housing design

・ Two or three stages can be in same housing

・ Reduction can be increased up to six stages with additional housing

・ Bearing solutions for high radial and axial loads

PARALLEL SHAFT GEARBOXES

・ Monoblock housing design

・ Two or three stages can be in same housing

・ Reduction can be increased up to six stages with additional housing

・ Bearing solutions for high radial and axial loads

・ Output shaft options (Hollow shaft, solid shaft, shrink disk, hollow and solid splines)

・ Extruder output option for extruder machines (DRE Type)

Frequency Inverter A2000 series

A2000 Series compact sensorless vector drive- Overload capacity is 150%(100%) of the rated current, 3s for 180% of the rated current; There are ten auxiliary frequency sources. It can implement fine tuning of auxiliary frequency and frequency synthesis, Two types of control mode: Sensorless flux vector control (VC), V/F(Voltage/Frequency) control.

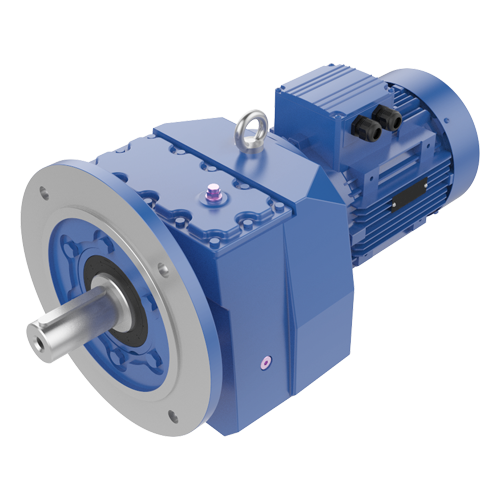

FLANGE MOUNTED HELICAL GEARBOXES

・ Monoblock housing design

・ Two or three stages can be in same housing

・ Reduction can be increased up to six stages with additional housing

・ Bearing solutions for high radial and axial loads

・ Output shaft options

HELICAL GEARBOXES

・ Monoblock housing design

・ Two or three stages can be in same housing

・ Reduction can be increased up to six stages with additional housing

・ Bearing solutions for high radial and axial loads

・ Output shaft options (Hollow shaft, solid shaft, shrink disk, hollow and solid splines)

・ Extruder output option for extruder machines (KRE Type)

FREQUENCY INVERTER b10 SERIES

・ Micro-compact, low cost;

・V/F control; built-in PID control, output frequency range 0.1~400 Hz;

・Extreme compact size saves installation space;

・DIN-rail mounting and wall mounting speed up installation space;

・Terminals uncovered, easy for wiring;

・Standard supports MODBUS via RS485, maintenance-free.

Planetary, flange mounted gearboxes

High torque density with the help of compact housing and bearings

・ Bearing solutions for high radial and axial loads

・ Output shaft options (Solid shaft, shrink disk, hollow shaft with splines, solid shaft with splines)

・ AC and hydromotor flanges

・ Perpendicular input shaft options with bevel gear stage

・ Worm and bevel gear unit coupling options to decrease output speed

・ Different cooling and lubrication options for different working conditions

Stepless speed motor – variators

Stepless speed motor-variators and motor-variators with gear reducers are developed on the basis of manufacture with advanced technologies that makes it specially adapted to work in ceramics, conveying, packing, chemical, textile, foodstuffs, machine-tools and all kinds of automatic production lines, pipelines and assembly lines which need speed-regulation,